A waterjet brick is rectangular piece of corrugated plastic, such as polypropylene, used instead of slats to support material. The waterjet will begin cutting, keep hand near pause (blue) button in case anything goes wrong iv.

Waterjet Cutting The Ultimate Guide Machinemfg

A water jet, also known as a waterjet or water jet cutter, is a fabricating tool machinist use for cutting a wide variety of materials or bulk materials.

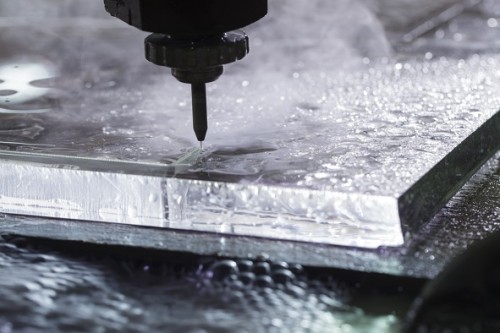

How to use a water jet cutter. Waterjet cutting involves jetting water at incredibly high speeds under very high pressure through a small opening. In this situation, try to take a sample of water from your waterjet supplier when you are having production cuts done. For this purpose, either specially treated water or an abrasive agent with the addition of sand is used.

The process is essentially the same as water erosion found in nature but. The resulting water jet cuts through where it’s aimed at by eroding the material where it contacts. The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal, stone or glass, while the terms pure waterjet.

Once the cut is finished hit “close” on the path control box When cutting materials with a thickness less than 2.5, the yield of medium or large cutting heads is not high. The jet then passes through a venturi section where a metered amount of granular abrasive is drawn into the water stream.

Only pure water is used for this test. We have also performed this test on our flowjet water jet cutter. It is most useful when machining tiny parts that could fall between the slats and get lost.

We use a vacuum assist valve that pulls the garnet through the nozzle before the jet turns on ensuring that the garnet hits the part before any water. However, interest has turned to using high pressure water jets as a means of cutting and drilling rock i._n lieu of conventional methods. The measured values during start, stop and pumping are continuously measured.

Waterjet is the most versatile process, because it. Water jet cutting is a manufacturing process that uses high pressure jets of water provided by pressurizing pumps that deliver a supersonic stream of water to cut and shape various types of materials. It makes cutting extremely quiet and significantly reduces splash back.

Why would you want to cut under water? The water in water jet cutting is pressurized to 392 mpa and projected using a small precision nozzle. Two types of cutting let us take a closer look at the basics of the two waterjet cutting methods.

Cut on top of waterjet brick or a sacrificial material to avoid frosting the back side of the glass with slat splashback. This mix of water and abrasive exiting the mixing tube is the visible cutting jet. Cut under water to minimize frosting.

Sometimes to increase the effectiveness of the waterjet cutting, we add some abrasive material to the water. The mixture of water and abrasive particles passes through a special ceramic mixing tube and the resulting abrasive/water slurry exits the. It also mixes water and an abrasive substance for cutting.

Muchnik of the leningrad mining institute In metals, the abrasive particles are responsible for the jet’s cutting ability, which occurs through erosion. Machinists use it in sheet metal cutting.

You may have an idea of what materials you might be cutting, but certainly not the entire universe of materials, especially if you run a job shop. To reduce the amount of chipping on the underside of the part, use a lower machinability to slow the glass cutting down even more than otherwise necessary. Simply gather a sampling of the overflow water and have it tested.

A waterjet cutter is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The abrasive does the cutting through a mechanical sawing action, leaving a smooth, precision cut surface. From our perspective they are interesting in that they can cut metal, something not normally possible with the laser cutters within our reach.

The following are the operating skills of water jets in various situations for your reference. The russians were the first to realize the potential of water jets.

Water Jet Water Jet Cutting Bohler Water Jet Abrasive Water Jet Cutting 2011

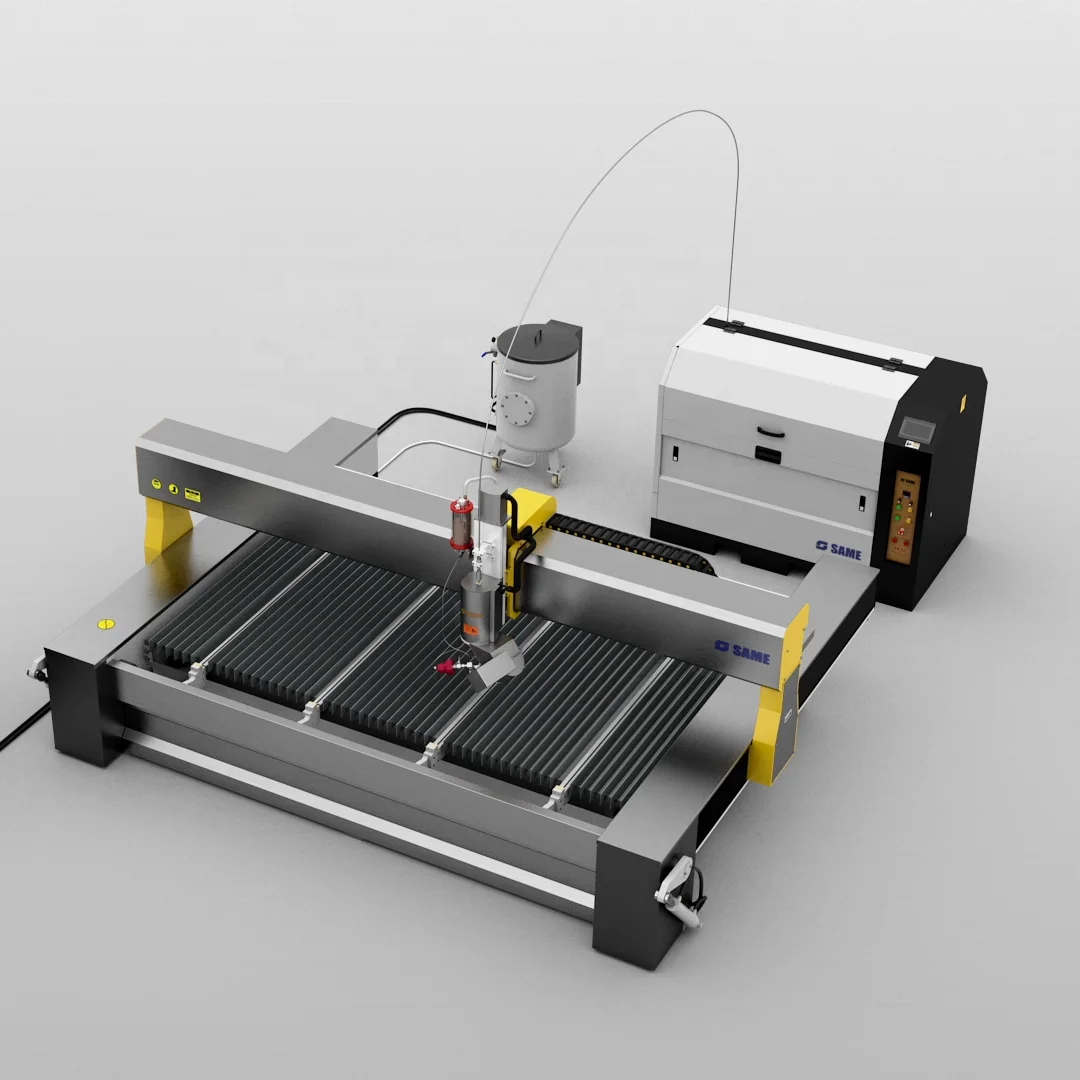

Yang Sama 50he-2516l-3x Water Jet Cutting Machine - Buy Desktop Air Jet Mesin Pemotongair Jetair Jet Cutter Product On Alibabacom

Water Jet Cutter - Wikipedia

Water Jet Cutter - Wikipedia

The Pressure Behind Abrasive Waterjet Cutting

3 Reasons To Use Waterjet Cutting - Swift Glass

Learn About Waterjets Abrasive Water Jet Cutting Machine

Operating Principle Of Water Jet Cutting 19 Download Scientific Diagram

Fast Extreme Water Jet Cutter Machine Working Modern Technology Waterjet Cutting Compilation - Youtube

How To Choose The Right Waterjet Cutting Machine

Water Jet Cutter - Wikipedia

Water Jet Cutter - Wikipedia

Cnc Water Jet All You Need To Know All3dp

Cnc Waterjet Cutting Machine From Water Jet Sweden

Water Jet Cutting Hydrodynamic Cutting - Openlearn - Open University

China High Pressure Cnc Waterjet Cutting Water Jet Cutter Machine Factory - China Waterjet Cutter Water Cutting

Benefits Of Waterjet Cutting - Fast Quality - Resato

Water Jet Cutting Through 3 Inch Thick Aluminum Metal 4 X 6 - Youtube

How Does Waterjet Cutting Work

Comments

Post a Comment